- HOME

-

PRODUCT

PRODUCT

Zhongjie special boiler products cover liquefied natural gas, liquefied petroleum gas, cryogenic containers, etc., and various specifications of containers meet the needs of all walks of life.

See More... -

CASE

LNG filling station Case study of fire insulation industry Food and beverage industry case Waterproof building materials industry case LNG gasification station Fertilizer industry case Drug industry case Hospital industry cases LNG urban peak shaving station Case study of plastic industry Feed industry case

-

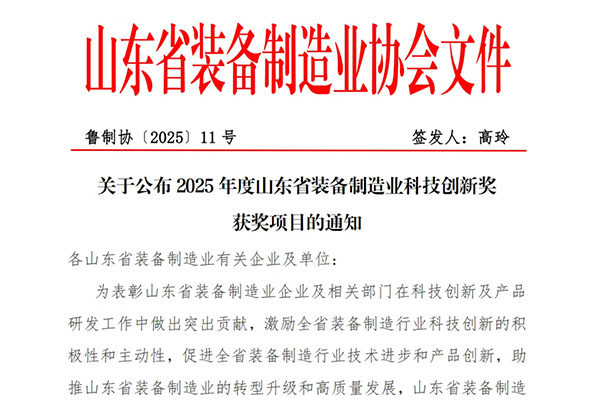

NEWS

NEWS

As a national high-tech enterprise, zhongjiete equipment attaches importance to scientific and technological R & D and innovation, widely carries out production, learning and research cooperation, and has a number of technical patents.

See More... -

SERVICE

SERVICE

As a national high-tech enterprise, zhongjiete equipment attaches importance to scientific and technological R & D and innovation, widely carries out production, learning and research cooperation, and has a number of technical patents.

See More... -

CONTACT

CONTACT

As a national high-tech enterprise, zhongjiete equipment attaches importance to scientific and technological R & D and innovation, widely carries out production, learning and research cooperation, and has a number of technical patents.

See More... -

ABOUT

ABOUT

As a national high-tech enterprise, zhongjiete equipment attaches importance to scientific and technological R & D and innovation, widely carries out production, learning and research cooperation, and has a number of technical patents.

See More... - LANGUAGE