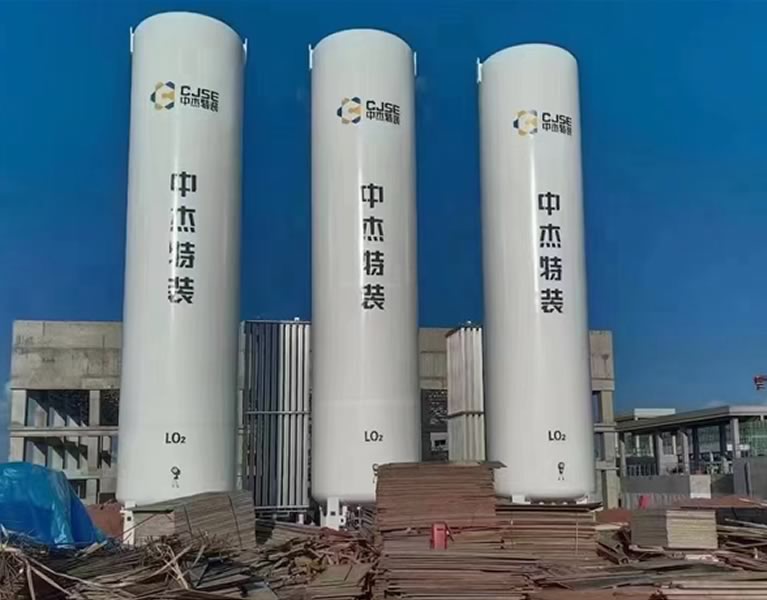

We produce 5 m3 to 150 m3 Cryogenic LCO2 Tank

Application of LCO2 tank

Cryogenic liquid LCO2 storage tank has double layers, inner layer adopts 16MnDR and outer layer adopts Q245R alloy steel, vertical structure, adopt vacuum powder insulation, with the advantage of compact structure, low daily evaporation rate, small footprint, centralized control, safe, reliable, easy operation and maintenance. We are able to make 5cbm - 150cbm LCO2 storage tank.

The cryogenic liquid LCO2 storage tank is mainly applied to chemical engineering,steel processing,machine manufacturing,nonferrous metal smelting,metal constructions,hospital,gas charging station and so on.It can not only fill the cryogenic liquid bottle directly but also gasification pressurized filling normal temperature high pressure gas cylinder or build centralized gas station.

Advantages of cryogenic storage tanks in Shandong Zhongjie Pressure Equipment:

1. Stainless steel purchases from the quality supplier to ensure the good quality of carbon steel liquid CO2 tank

2. Cryogenic storage tank’ materials are re-inspected according to GB150-2011 "Pressure Vessel", the material is cut by CNC plasma cutting machine, and the geometrical dimensions of the barrel section are strictly packed.

3. the longitudinal and circumferential seam welding are all welded by submerged arc welding, the appearance is well formed, and the inner tank of cryogenic tank is subjected to 100% X-ray inspection.

4.The elbow is bent on the CNC pipe bending machine, which strictly guarantees the geometrical dimensions of the elbow.

5.The inner and outer surfaces of the stainless steel inner tank are degreased and pickled and passivated. The inner and outer surfaces of the carbon steel shell are sandblasted and rusted.

6.The sand loading process adopts negative pressure filling and positive pressure compaction to ensure the uniformity of the sandwich pearl sand and ensure the cold preservation effect of the inter layer.

7.We can manufacture horizontal and vertical standardized liquid gas storage tank.

8.If you need customized tanks,we also offer chemical non-standard tank service. As the largest tank production base in China, we have first-class design and advanced production technology. Accordingly, we will product a set of high-quality equipment in the shortest time as long as you provide us with the detailed technical data.Besides,we also have obtained ASME S / U / U2 qualification certification.

Technical data we can provide

⑴ We will supply Product quality certificate of cryogenic tank 1 set( send with equipment)

⑵ We can provide Record drawings 1 set each( send with equipment)

⑶ We will provide Strength calculation list 1 set each( send with equipment)

⑷ We will supply Operating manual 1 set each( send with carbon steel liquid CO2 tank)

⑸ We will supply Equipment flow chart and foundation drawing 1 set each

Models of LCO2 Storage Tank

Model | Medium | Cryogenic Tank Dimension (mm) | Weight of Tank (kg) |

CFL-5/2.16(A) | LCO2 | Φ 1916 x 5254 | 4800 |

CFL-10/2.16(A) | LCO2 | Φ 2316 x 5951 | 7200 |

CFL-15/2.16(A) | LCO2 | Φ 2416 x 7402 | 9900 |

CFL-15/2.16(B) | LCO2 | Φ 2416 x 7202 | 9600 |

CFL-20/2.16(A) | LCO2 | Φ 2616 x 7929 | 12400 |

CFL-20/2.16(B) | LCO2 | Φ 2616 x 7629 | 12000 |

CFL-30/2.16(A) | LCO2 | Φ 2916 x 8909 | 17300 |

CFL-30/2.16(B) | LCO2 | Φ 2916 x 8546 | 16700 |

CFL-40/2.16(A) | LCO2 | Φ 3016 x 10540 | 21900 |

CFL-40/2.16(B) | LCO2 | Φ 3016 x 10180 | 21200 |

CFL-50/2.16(A) | LCO2 | Φ 3016 x 12709 | 26100 |

CFL-50/2.16(B) | LCO2 | Φ 3016 x 12150 | 25200 |

CFL-60/2.16(A) | LCO2 | Φ 3016 x 15200 | 30500 |

CFL-60/2.16(B) | LCO2 | Φ 3016 x 14550 | 29200 |

CFL-80/2.16(A) | LCO2 | Φ 3520 x 14019 | 43700 |

CFL-80/2.16(B) | LCO2 | Φ 3520 x 13419 | 41900 |

CFL-100/2.16(A) | LCO2 | Φ 3520 x 16919 | 37200 |

CFL-100/2.16(B) | LCO2 | Φ 3520 x 17276 | 49700 |

CFL-150/2.16(A) | LCO2 | Φ 3724 x 22080 | 75600 |

CFL-150/2.16(B) | LCO2 | Φ 3724 x 21090 | 72400 |

Specifications of LCO2 Storage Tank

Item | Unit | Indicator (parameters) | Remark |

Vessel type |

| Inner Container | Shell |

|

Ⅱ type |

|

Filling medium |

| LCO2 |

|

Design temperature | ℃ | -40 | 50 |

|

Body materials |

| 16MnDR | Q245R |

|

Welded joint coefficient |

| 1.0 | 0.85 |

|

Non-destructive testing |

| 100% RT (A、B type) | 20%RT+100% PT/MT (A、B type) | NB/T47013-2015 |

Corrosion allowance | MM | 0 | 0 |

|

Insulated form |

| T-60D pearl sand (vacuum powder) |

|

Design using life |

| 20 Years |

|

Manufacturing acceptance standard: GB/T18442 |

Technical Support

1. Installation Training Our company can guide the equipment installation and debugging, ensure the boiler installation quality and commissioning are smooth, Also , we can train the equipment operation management personnel free of charge for users, and ensure the stable and safe operation of the equipment.

2. Quick Response After receiving the user demand notice, our technical support personnel will take the fastest means of transportation to the site for troubleshooting.

3. After Service Provide follow-up services, establish customer archives, visit and find out the operation of the equipment regularly to ensure the efficient and stable operation of the equipment.

4. Real-time Online In order to answer the user's problems in time, we open the after-sales service hotline for 24 hours.

5. Warranty Period Under the normal use of the user, the equipment is guaranteed for 12 months and maintained for life.

If any products meet your demand,please feel free to contact us.

E-mail:zhangteng@c-jsec.com

Tel/Fax:+86-530-7355311

WhatsApp: +86 13269593030